New Air-Powered Computer Transforms Healthcare

A new air-powered computer detects the failure of medical equipment using air pressure, eliminating electronics for a safer, cheaper method. Future plans include expanding its use to hazardous areas.

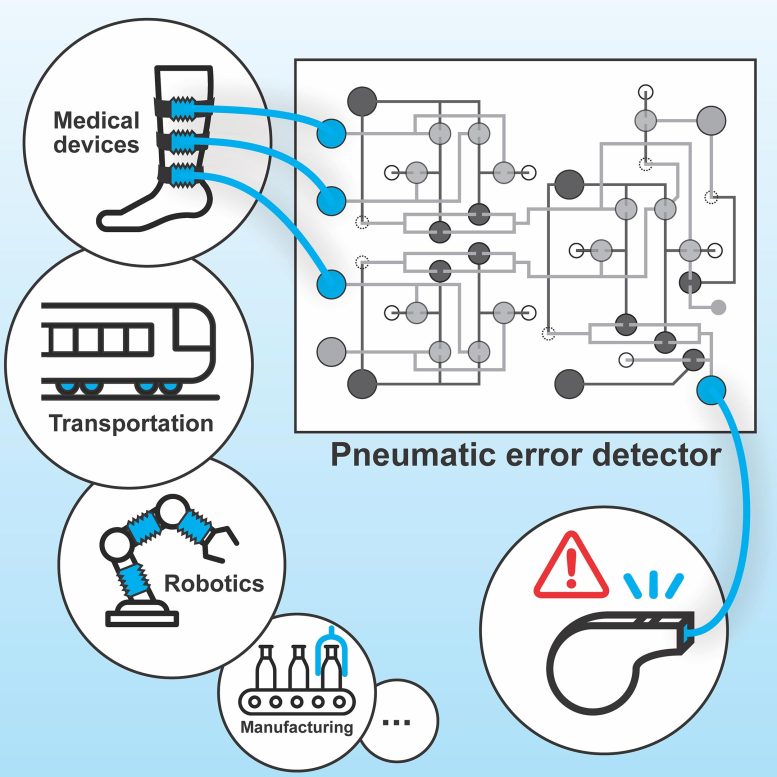

Researchers have developed an airborne computer that can detect and issue warnings when certain medical equipment fails. This device simplifies the monitoring process by eliminating the need for electronic sensors, providing a cost-effective and reliable way to help prevent bleeding and strokes.

A computer, outlined in newsprint The deviceit not only travels through the air but also uses the air to give warnings. It immediately beeps when it detects a problem with the life-saving compressor it’s designed to monitor.

Improving the Safety of Medical Devices with Pneumatic Technology

Intermittent IPC devices are leg cuffs that periodically inflate and squeeze the person’s legs to increase blood flow. This prevents lesions that lead to blockage of blood vessels, stroke, or death. Typically, these machines are controlled and monitored by electronic devices.

“IPC devices can save lives, but all the electronics in them make them expensive. So, we wanted to create an air device that eliminates other electronic devices, making these devices cheaper and safer,” said William Grover, assistant professor of bioengineering at UC Riverside and corresponding author of the paper.

Technical Specifications: How Airborne Computers Work

Pneumatics move compressed air from one place to another. Emergency brakes on freight trains work this way, as do bicycle pumps, tire pressure gauges, respirators and IPC devices. It made sense to Grover and his colleagues to use one air conditioning device to control the other and make it safer.

This type of device works in a similar way to electronic circuits, by performing parity bit calculations. “Let’s say I want to send a message with ones and zeros, like 1-0-1, three bits,” Grover said. “Decades ago, people realized that they could send these three components in one light to make sure that the receiver gets the right message.”

That extra bit is called a parity bit. The minimum is a number — 1 if the message has an odd number of bits and 0 if the message has an even number of bits. If the first number appears at the end of a message with even bits, it is clear that the message was wrong. Most electronic computers send messages this way.

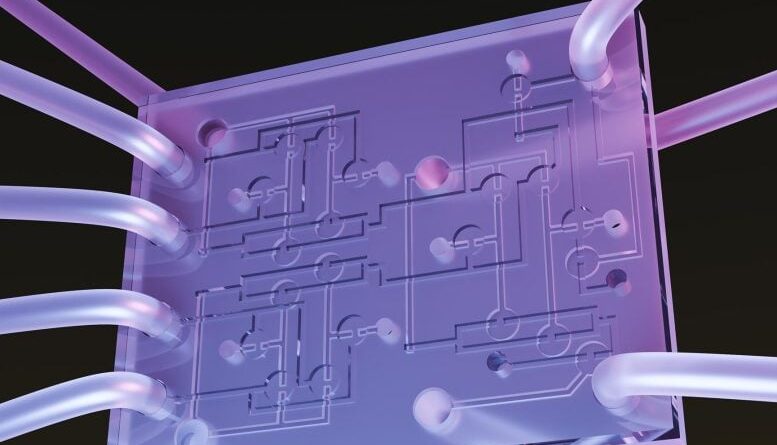

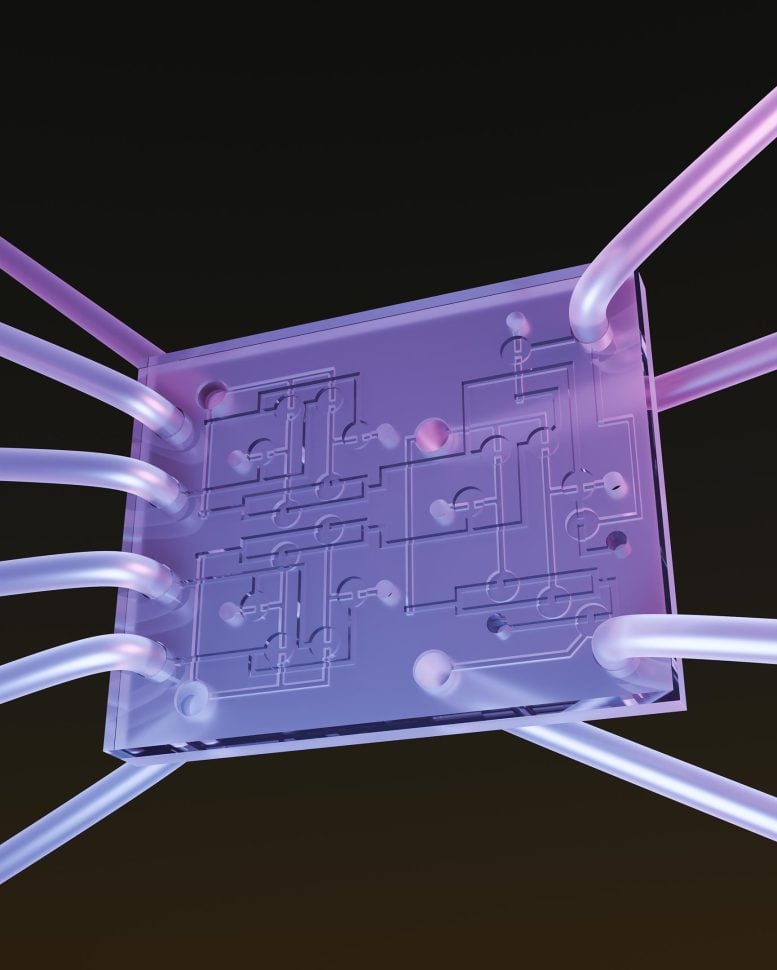

A display of a pneumatic logic sensor designed to detect operational errors in compression equipment. Credit: William Grover/UCR

Practical Applications and Future Prospects

The pneumatic computer uses the differences in air pressure flowing through 21 small valves to calculate the zeros and zeros. If no reading error has occurred, the whistle does not sound.

If it blows, that is a sign that the machine needs to be repaired. In a video showing the air computer, Grover and his students are shown destroying the IPC device with a knife, rendering it unusable. Seconds later, a whistle blows.

“This device is about the size of a matchbox. It replaces a few sensors as well as a computer,” said Grover. “Therefore, we can reduce the cost while we see the problems of the device. It can also be used in conditions of high humidity or high temperature that are not suitable for electronic devices.”

IPC device monitoring is only one device for air computing. For his next project, Grover would like to invent a device that would eliminate the need for the annual human-killing task of rotating grain over tall silos.

Tall buildings filled with corn or wheat, grain silos are a common sight in the Midwest. Often, one has to go inside with a shovel to break up the grain and even the piles inside.

“A surprising number of people die because the grain changes and a person gets trapped. A robot could do this job instead of a person. However, these silos explode, and the spark one electric one can blow up a silo, so an electronic robot might not be the best choice,” Grover said. “I want to make an aerial robot that can work in this explosive environment, doesn’t produce sparks, and gets people out of harm’s way.”

Airborne computing is a concept that has been around for at least a century. People used to make wind-powered pianos that could play music out of paper rolls. After the rise of the modern computer, engineers lost interest in air circuits.

“Once a new technology becomes dominant, we lose the knowledge of solutions to other problems,” Grover said. “One thing I like about this research is that it can show the world that there are situations today when the thoughts of people 100 years old can still be useful.”

Reference: “Air-driven logic circuits for lung system fault detection” by Shane Hoang, Mabel Shehada, Zinal Patel, Minh-Huy Tran, Konstantinos Karydis, Philip Brisk and William H. Grover, 12 August 2024 , The device.

DOI: 10.1016/j.device.2024.100507

#AirPowered #Computer #Transforms #Healthcare